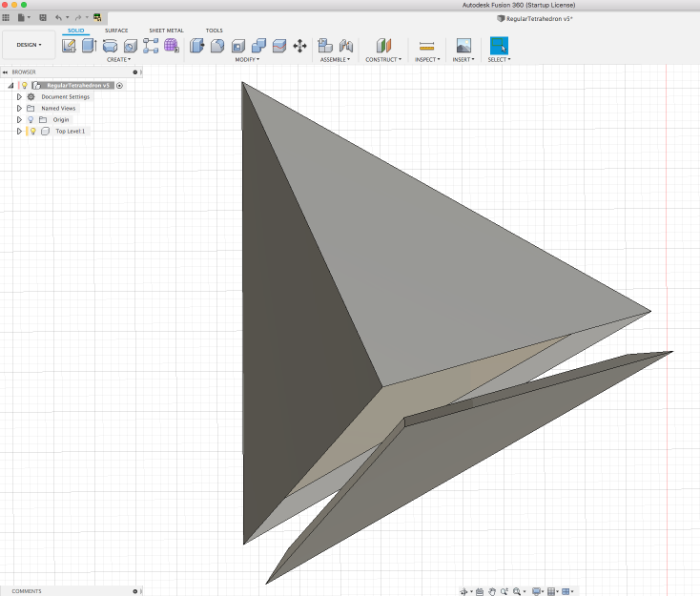

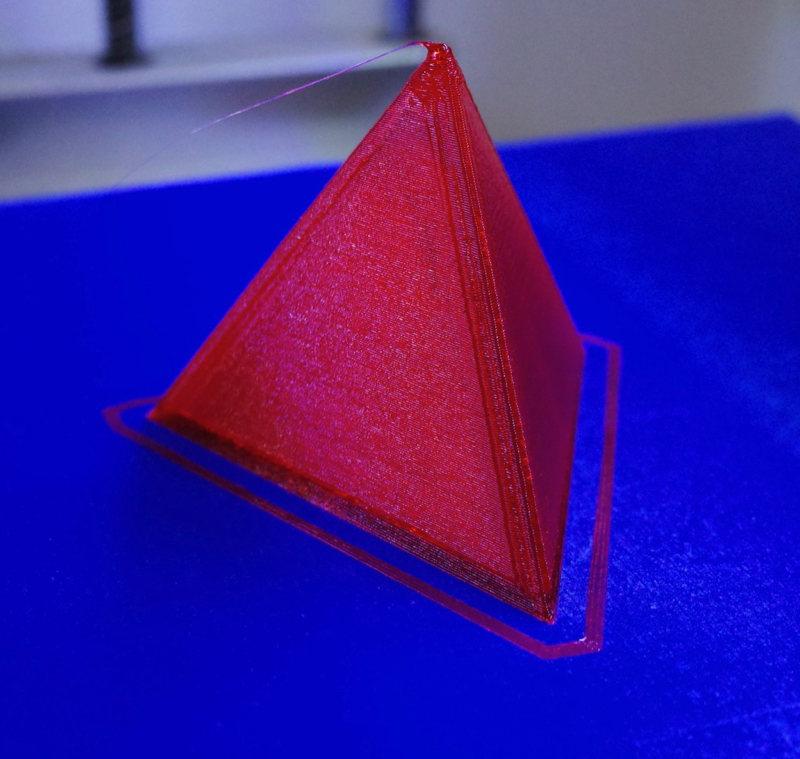

My latest fascination has been regular tetrahedrons. My goal is to fabricate these in stainless steel.

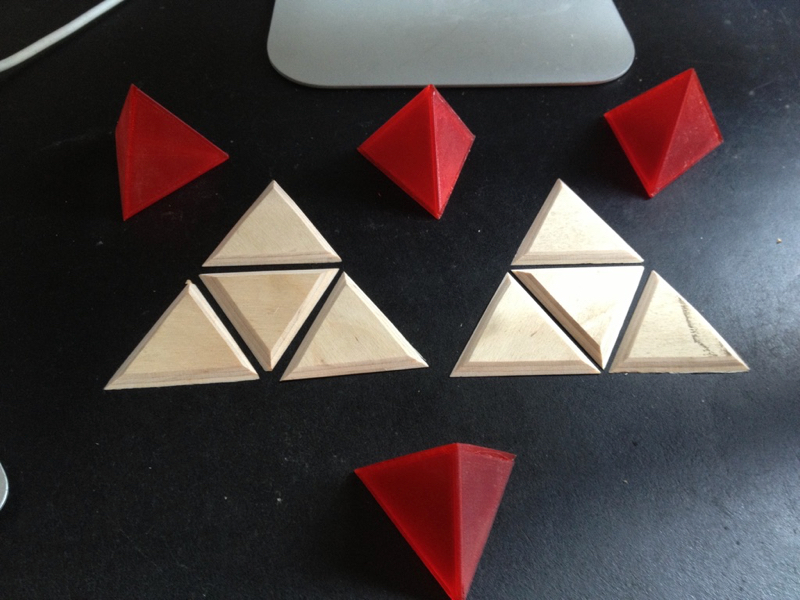

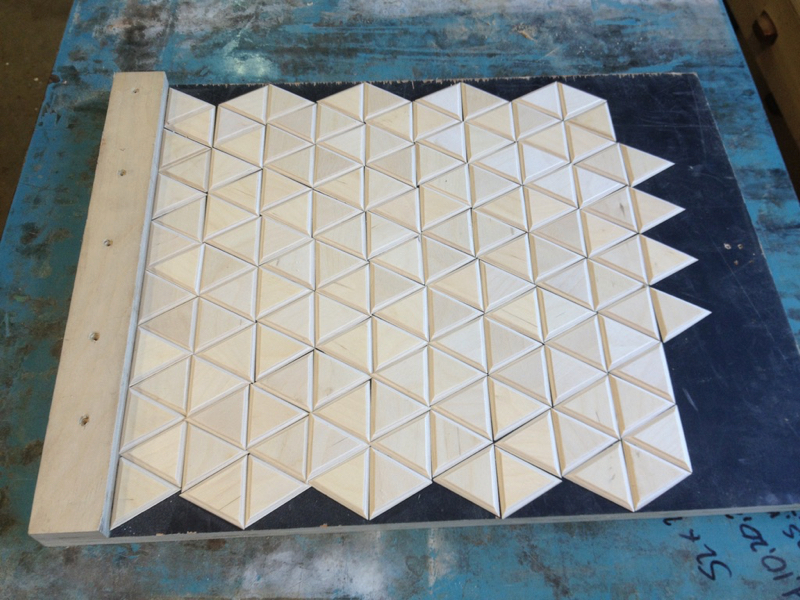

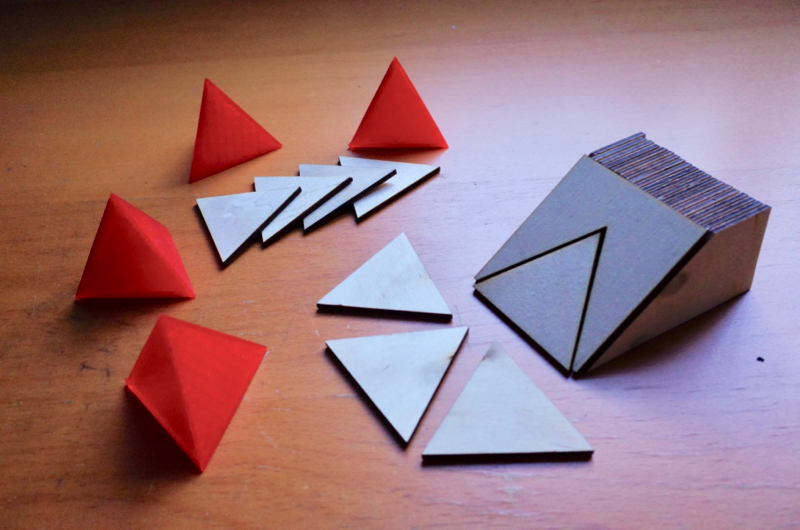

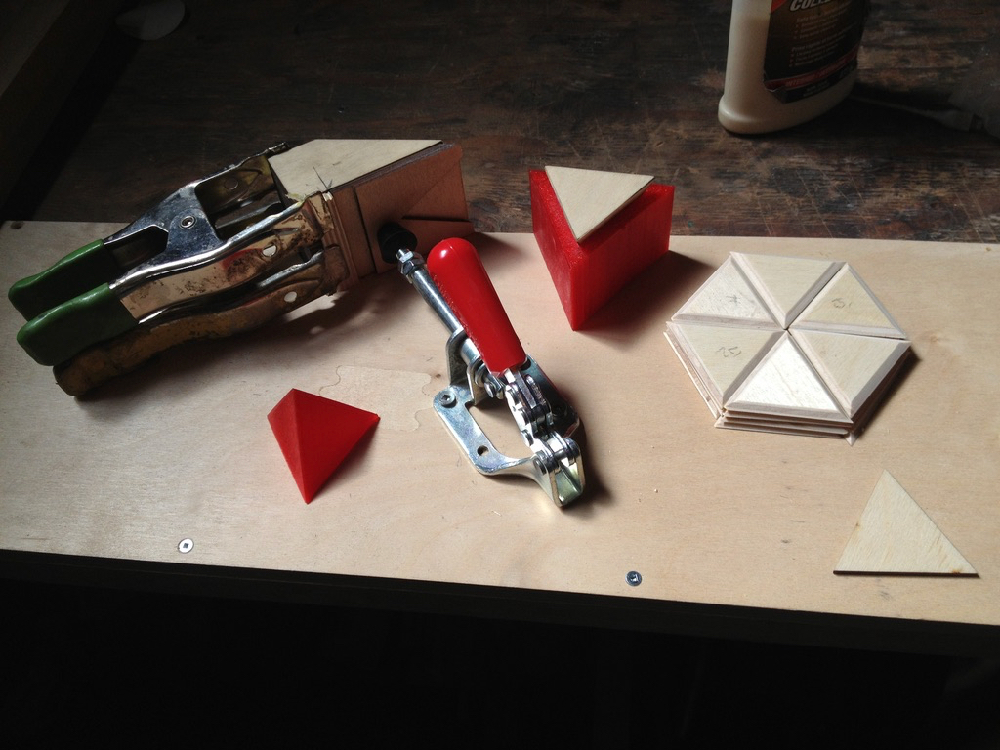

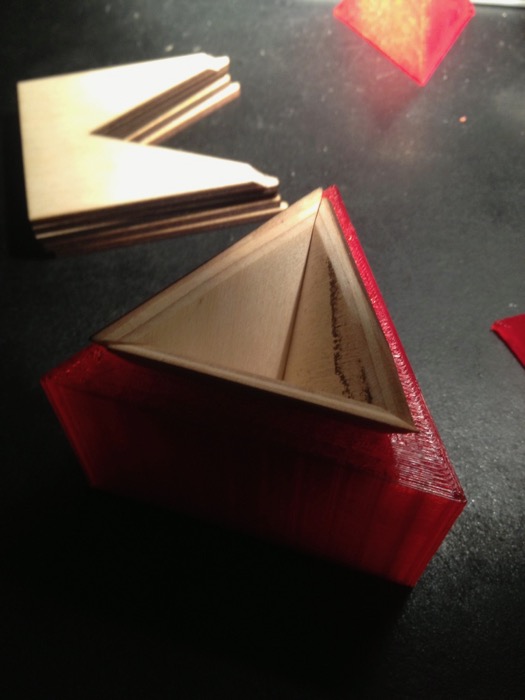

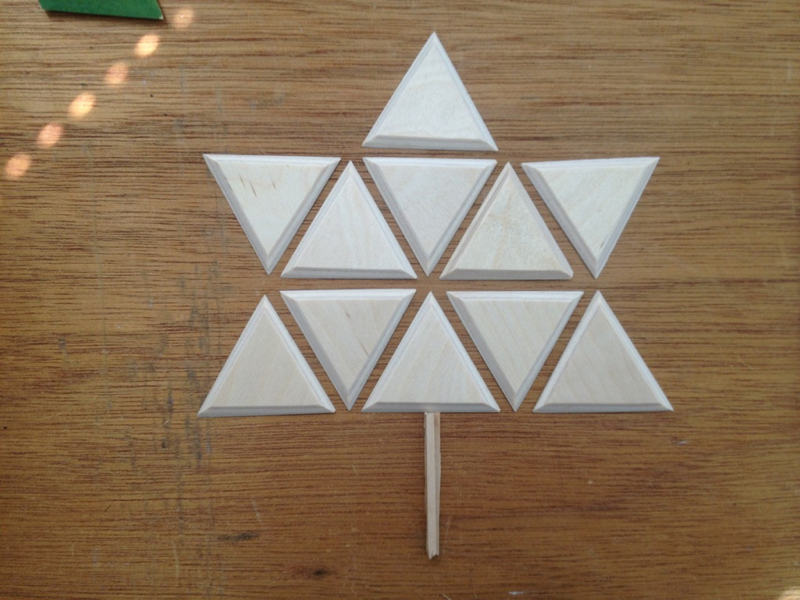

To start, I modelled a regular tetrahedron in Fusion 360 and 3D printed a few as a sanity check. From there, I moved on to making them from 3 mm Baltic birch plywood. Each tetrahedron requires laser cutting four equilateral triangles. After cutting, I use a sanding jig to bevel the three edges of each triangle to the correct angle so the sides fit together cleanly without gaps.

For assembly, I use a glue-up jig that holds the triangles in place. The core process—cutting, beveling, and glueing—takes about five minutes per tetrahedron.

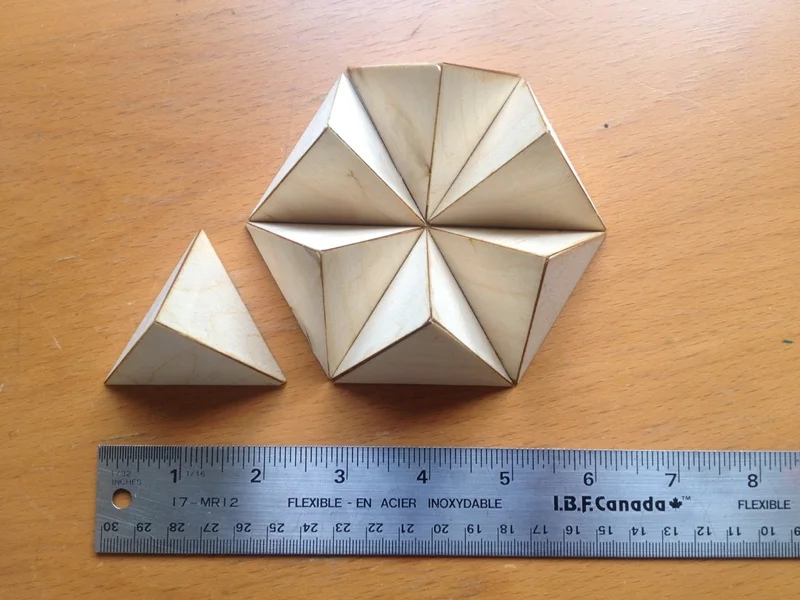

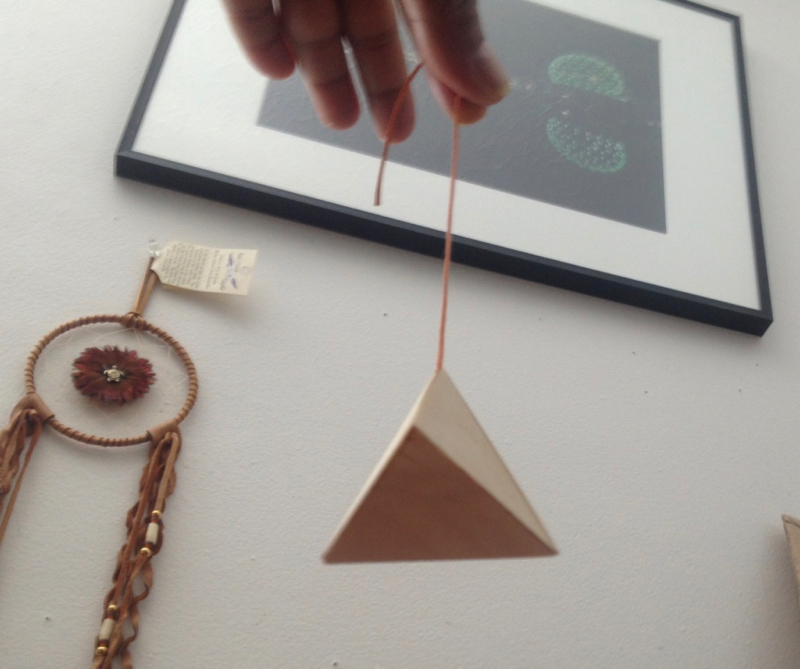

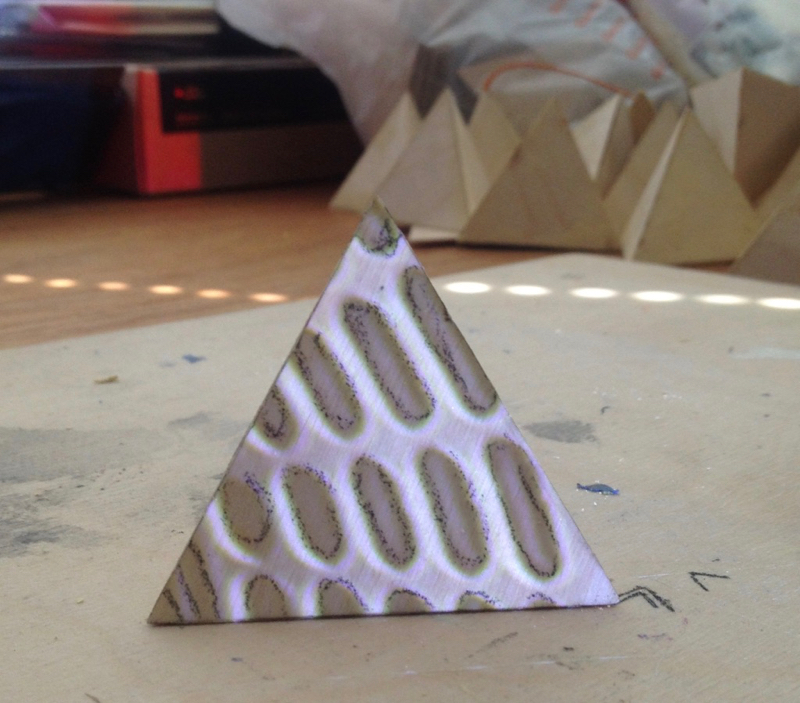

To prepare each tetrahedron as a painting surface, I fill any cracks with wood filler, sand each side, and apply gesso to all four faces. This creates a smooth, paint-ready surface.

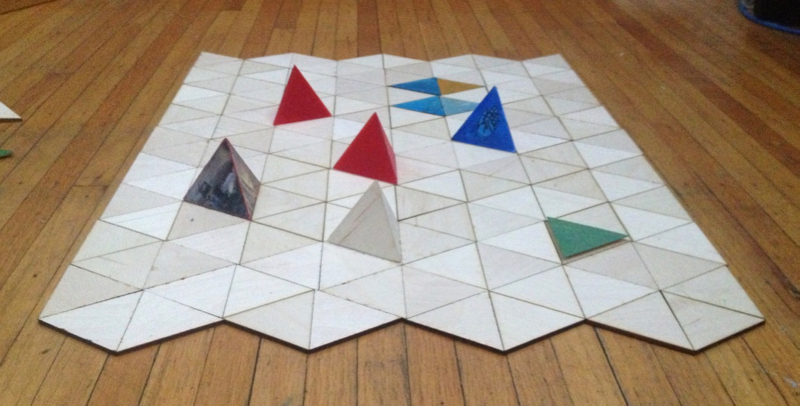

Each tetrahedron offers four perfect faces for miniature artwork. Grouped together, they can form larger sculptural or wall-mounted pieces. The potential for repeating patterns—in both 2D and 3D—is endless. I am looking forward to exploring the possibilities of this space.